spring cone crusher

Usage and application:

Spring cone Crusher is normally to crush mid-hard and above mid-hard ores and rocks. It is popular stone crushing machines in manufactured sand production, aggregates production and mining operations. Cone crusher is used in secondary, tertiary crushing stages.

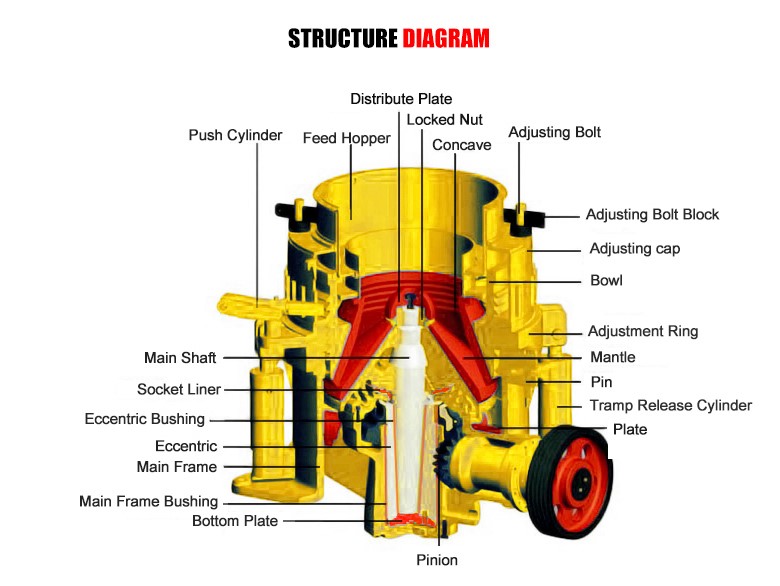

Working principle:

Sping cone crusher consist of frame, transmission device( countershaft, countershaft bushing, gear and pinion), main shaft, eccentric shaft, cone,mantle, bowl-shaped bearing, springs and hydraulic pressure station for adjusting discharge opening.

(1) Transmission device: Countershaft assembly is supported by the bronze countershatf bushings, can be dismounted for convenience of maintence. And the gear and pinipn with high strengh and high precision are adopted to ensure the reliable operation of equipment.

(2) Main shaft: Forged form hardened and tempered chrome molybdenum steel particularly large diameter to suit wear-resisting application. High quality copper socket liner can bear high crushing load, and allows the machine working under rigorous condition.

(3) Cone and mantle plate, high manganese steel casting, hydraulic lock device is convenient and reliable.

(4) Spring and hydraulic device: Convenient for adjusting the discharge size, can remove the foreign materials if non-crushable objects came into the crushing chamber.

Features:

(1) Our cone crusher has the characteristics of large breaking force, high efficiency, high crushing capacity, low operating cost and long service life. It is convenient to operate and is economical.

(2) The crushed materials are of equal size, thus reducing circulating load.

(3) Large and medium-sized crushers adopt hydraulic chamber-cleaning systems, which will help reduce the down time.

(4) Cone crushers with different chambers are available, to meet our customers' requirements.

(5) Grease seal can effectively avoid the blockage of water feeding system and drainage system, as well as mixing of water and oil.

(6) As the overload protection device, spring safety device allows foreign matter and iron pieces to pass through the crushing chamber without jeopardizing machines.

Main technical specifications:

|

Model |

Diameter of crushing cone(mm) |

Feeding size(mm) |

Adjusting Range of Discharge Opening(mm) |

Capacity(t/h) |

Power(KW) |

|

PYB600 |

Φ600 |

≤ 75 |

12-25 |

15-25 |

30 |

|

PYD600 |

Φ600 |

≤ 35 |

3-13 |

5-23 |

30 |

|

PYB900 |

Φ900 |

≤ 115 |

15-50 |

50-90 |

55 |

|

PYZ900 |

Φ900 |

≤ 60 |

5-20 |

20-65 |

55 |

|

PYD900 |

Φ900 |

≤ 50 |

3-13 |

15-50 |

55 |

|

PYB1200 |

Φ1200 |

≤ 145 |

20-50 |

110-168 |

110 |

|

PYZ1200 |

Φ1200 |

≤ 100 |

8-25 |

42-135 |

110 |

|

PYD1200 |

Φ1200 |

≤ 50 |

3-15 |

18-105 |

110 |

|

PYB1750 |

Φ1750 |

≤ 215 |

25-50 |

280-480 |

160 |

|

PYZ1750 |

Φ1750 |

≤ 185 |

10-30 |

115-320 |

160 |

|

PYD1750 |

Φ1750 |

≤ 85 |

5-13 |

75-230 |

160 |

|

PYB2200 |

Φ2200 |

≤ 300 |

30-60 |

490-750 |

260-280 |

|

PYZ2200 |

Φ2200 |

≤ 230 |

10-30 |

200-580 |

260-280 |

|

PYD2200 |

Φ2200 |

≤ 100 |

5-15 |

120-340 |

260-280 |

Get a Quote