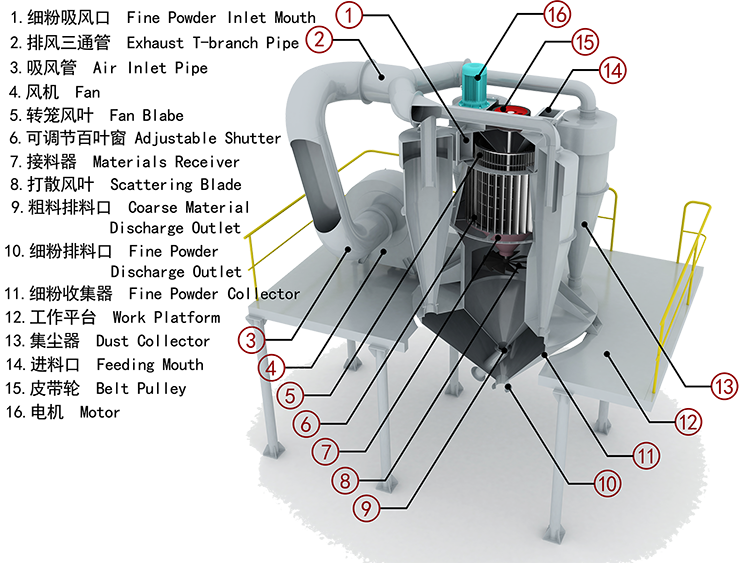

powder classifier

Usage and application:

Powder classifier is mainly used for raw meal clinker classifying and setting up close-circuit grinding system with ball mill. It is widely used in powder process, cement, chemical, metallurgical and other industries.

Working principle

Powder classifier often work with ball mill, forming a closed- circle production plant.it can improve ball mill capacity and get required material size. it's widely used for cement production, fly ash production, sand production and so on. more than 300mesh powder can be get. In working condition,high speed motor drives the vertical transmission shaft to rotate through the transmission device. The material access the chamber of separator by the feeding port which on the top of separator, then falls on the scattering plate by two pyramidal which set in the coarse powder collecting cone and powder pipe. The fine powder which satisfied demand will enter inside through the cage rotor,with circulating air enters the high efficiency and low resistance cyclone separator, then slipped into fine powder collecting cone into a finished product.

Features:

1.Innovative design:With a new-style assembled design method,it is integrated with the advantages of the original centrifugal type, cyclone type,and double rotor type,which greatly lower energy consumption;

2.High efficient and low energy consumption:Materials are classified in several classifying areas,with unique distribution structure.It can make excellent powder-selection with a high efficiency of over 85%.And the electrical power consumption is 30% lower than the traditional powder selector cost;

3.Adjusting standard:This machine effectively improves the grain grade of the final product and enhances the cement quality to adjust to the national new cement standard;

4.Condensation resistant:With available condensation resistant design,it can in the season with the southern's high moisture and northern's cold climates;

5.Advanced and durable:Multiple-section scale board can prolong the frame's service life.It has a compact structure,including a fan,adjusting motor,lock air valve and so on.

Technical specifications:

|

Model |

Fineness (%) |

Wind Capacity (m3/h) |

Rotate speed (rpm) |

Power (kw) |

Max capacity (t/h) |

Capacity (t/h) |

|

TS-I |

0-3 |

16000 |

250-500 |

15 |

50 |

10-18 |

|

TS-II |

0-3 |

22000 |

220-450 |

18.5 |

90 |

15-28 |

|

TS-III |

0-3 |

30000 |

180-400 |

22 |

120 |

20-40 |

|

TS-IV |

0-3 |

45000 |

160-340 |

30 |

150 |

30-50 |

|

TS-V |

0-3 |

60000 |

130-300 |

30 |

210 |

40-70 |

|

TS-VI |

0-3 |

75000 |

130-260 |

37 |

260 |

50-85 |

|

TS-VII |

0-3 |

95000 |

120-240 |

45 |

330 |

75-110 |

|

TS-VIII |

0-3 |

120000 |

110-200 |

55 |

400 |

95-130 |

|

TS-IX |

0-3 |

150000 |

110-180 |

75 |

500 |

110-160 |

|

TS-X |

0-3 |

180000 |

110-160 |

110 |

600 |

130-190 |

Get a Quote