bucket elevator

Usage and application:

Bucket Elevator is a kind of conveying equipment used for conveying bulk materials vertically, maximum transport height is 60 m. It is widely used in the cement industry, chemical industry, power plant, grain storage and other industry etc,For conveying cement, cement clinker, crushed lime, sand, compound fertilizer, coal, grain and other bulk material etc.

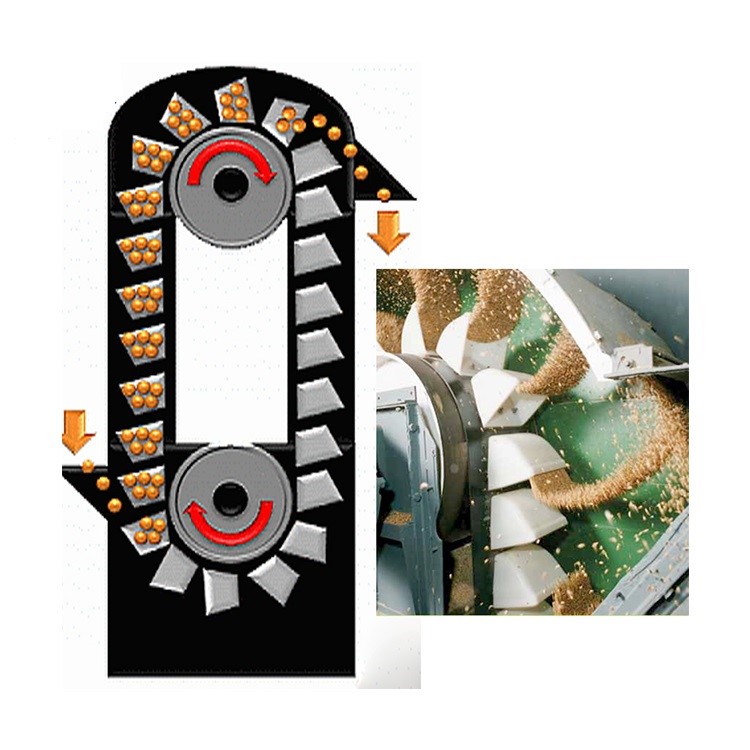

Working Principle

Material is fed into an inlet hopper. Buckets dig into the material, and convey it up to and over the head sprocket/pulley, then throwing the material out the discharge throat. The emptied buckets then continue back down to the boot to continue the cycle.

Features :

1).Bucket elevator has less requirement on materials, features and the bulk. It can lift, the powder, granular and bulk materials.

2).The max lifting capacity is 4,600m3/h.

3).Bucket elevator adopts inflow feeding, gravity induced discharge, and use large capacity hopper.

4).The traction parts adopt wear-resistant chains and steel wire belt to extend the service life of the traction parts.

5).Bucket elevator runs smoothly, generally the lifting height is 40m or even higher.

Technical specification:

|

Model |

Capacity |

Bucket |

Round links chain |

Sprocket pitch |

Max. Granularity |

|||

|

width |

volume |

pitch |

speed |

|||||

|

(m³) |

(mm) |

(L) |

(mm) |

(m/s) |

(mm) |

(m/m) |

(mm) |

|

|

TH160 |

8-12 |

160 |

1.2 |

320 |

125 |

ø8x30 |

400 |

18 |

|

TH200 |

13-22 |

200 |

2.1 |

400 |

1.25 |

ø12x40 |

500 |

25 |

|

TH250 |

16-28 |

250 |

3.0 |

500 |

1.4 |

ø18x50 |

600 |

32 |

|

TH315 |

21-36 |

315 |

4.0 |

500 |

1.4 |

ø18x50 |

630 |

45 |

|

TH400 |

36-56 |

400 |

5.9 |

600 |

1.4 |

ø18x50 |

710 |

55 |

|

TH500 |

45-70 |

500 |

9.3 |

688 |

1.5 |

ø22x86 |

800 |

75 |

|

TH630 |

68-110 |

630 |

14.6 |

920 |

1.6 |

ø22x86 |

900 |

85 |

|

TH800 |

87-140 |

800 |

23.3 |

920 |

1.6 |

ø26x92 |

1000 |

100 |

|

Item |

Conveying capacity (m³/h) |

Hopper |

Max aggregate diameter (mm) |

Spindle speed (r/s) |

Material bulk density (t/m³) |

Max hoisting height (m) |

Power (kw) |

|||

|

Volume (L) |

Bucket chain pitch (mm) |

Hopper width (mm) |

Bucket speed (m/s) |

|||||||

|

NE15 |

10~15 |

2.5 |

203.2 |

250 |

0.5 |

40 |

15.54 |

0.6~2.0 |

35 |

1.5~4 |

|

NE30 |

18. 5~31 |

7.8 |

304.8 |

300 |

0.5 |

55 |

16.45 |

0.6~2.0 |

50 |

1.5~11 |

|

NE50 |

35~60 |

14.7 |

304.8 |

300 |

0.5 |

60 |

16.45 |

0.6~2.0 |

45 |

1.5~18.5 |

|

NE100 |

75~110 |

35 |

400 |

400 |

0.5 |

70 |

14.13 |

0.6~2.0 |

45 |

5.5~30 |

|

NE150 |

112~165 |

52.2 |

400 |

600 |

0.5 |

90 |

14.13 |

0.6~2.0 |

45 |

5.5~45 |

|

NE200 |

170~220 |

84.6 |

500 |

600 |

0.5 |

100 |

10.9 |

0.6~1.8 |

40 |

7.5~55 |

|

NE300 |

230~340 |

127.5 |

500 |

600 |

0.5 |

125 |

10.9 |

0.6~1.8 |

40 |

11~75 |

|

NE400 |

340~450 |

182.6 |

600 |

700 |

0.5 |

130 |

8.3 |

0.6~1.8 |

30 |

18.5~90 |

|

NE500 |

450~550 |

260.9 |

700 |

700 |

0.5 |

140 |

7.1 |

0.6~1.8 |

30 |

30~110 |

|

NE600 |

550~660 |

330.2 |

700 |

700 |

0.5 |

150 |

7.1 |

0.6~1.8 |

30 |

37~132 |

|

NE800 |

680~830 |

501.3 |

800 |

800 |

0.5 |

165 |

6.2 |

0.6~1.8 |

30 |

~160 |

Get a Quote