MW micro powder mill

Usage and application:

MW Series Micro Powder Mill is equipment designed for customers who need to make ultra-fine powder. This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise. And the whole production won’t take effect on environment.

Applications: Chemical Industry, paint, cosmetics, medicine, food additive,etc.

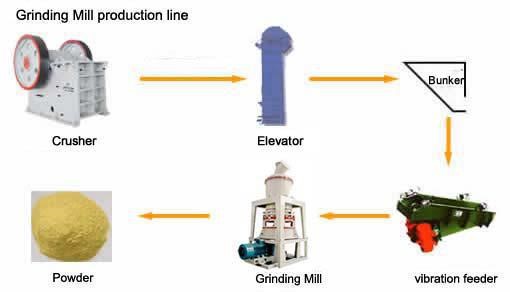

Working principle:

MW micro powder grinding mill mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

The motor drives the main shaft and every turnplate through the reducer. The reducer drives dozens of rollers to rotate against race way of ring through pin. Small material crushed by hammer crusher is transported into hopper by elevator, and then vibrating feeder shall feed material to the central part of upper turnplate evenly. The material falls to circle under the centrifugal force and comes down to raceway of ring to be crushed into powder. After grinded in the first race way, the material goes to the second and third turnplate. The blower inhales the external air into the mill and carries the powder after third turnplate into powder-separator. Turbine in the separator makes the coarse powder drop down and regrinded and the fine powder shall go into cyclone powder collector together with air current and go down through discharge valve as final product; at the same time, air current with a little dust goes out through blower and muffler after purified by filter.

Features:

High Efficiency

Under the same finished final size and the same motor power, the capacity of CLIRIK limestone micro powder grinding mill twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization,the lifetime can reach 2-5 years for grinding calcite carbonate.

High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.

Technical specifications:

|

Model |

Maximum feed size (mm) |

Output fineness (μm/mesh) |

Capacity (t/h) |

Dimension (m) |

Main mill Power (kw) |

|

MW880 |

≤10 |

5-45 |

0.5-5 |

16700*3400*7300 |

75 |

|

MW980 |

≤15 |

5-45 |

0.6-6.5 |

14700*4800*7200 |

2*45 |

|

MW1080 |

≤15 |

5-45 |

1-8.5 |

22700*36500*8600 |

132 |

|

MW1280 |

≤20 |

6-45 |

1.5-12 |

27320*4500*10250 |

185 |

|

MW1680 |

≤20 |

9-100 |

3.8-30 |

26300*7500*11900 |

315 |

Get a Quote