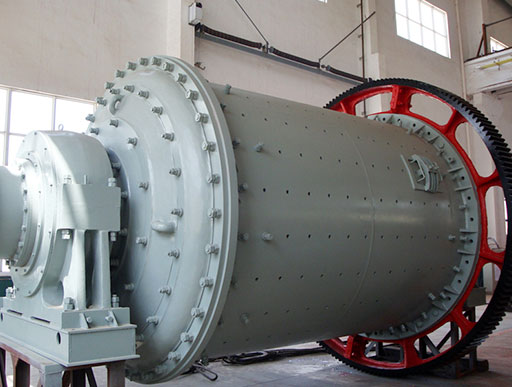

quartz ball mill

Usage and application:

Quartz ball mill is a key equipment for material grinding after crushing process.The quartz ball mill can be used to grind different types of quartz minerals, such as quartzite, sand stone and quartz sand. It is widely used in powder-making production lines, such as cement, silicate, new-type building material, refractory material, fertilizer, glass ceramics and non-ferrous metal etc.

Working principle:

After being crushed by the quartz crusher, the quartz is lifted to the storage hopper by the elevator, and the material is discharged from the storage hopper, and then evenly transported into the barrel of the quartz ball mill by the feeder.

The material is loaded into the barrel by the hollow shaft at the feeding end of the quartz sand ball mill. When the barrel rotates, the grinding steel balls and materials are attached to the barrel liner plate under the action of inertia, centrifugal force and friction force, and are carried to the height by the barrel. When the materials and the grinding steel balls are brought to a certain height, they are thrown down due to their own gravity, and the falling grinding steel balls crush the material in the barrel.

Features:

Suitable for grinding material with high hardness

No pollution for the powder with ceramic liner and ceramic ball

Stable performance Easy installation

The capacity and fineness can be adjusted by adjusting the diameter of the ball

Technical specifications:

|

Model |

Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging size (mm) |

Capacity |

Motor (kw) |

Weight (t) |

|

(t/h) |

|||||||

|

Φ900*1800 |

36-38 |

1.5 |

<=20 |

0.075-0.89 |

0.65-2 |

18.5 |

4.6 |

|

Φ900*3000 |

36 |

2.7 |

<=20 |

0.075-0.89 |

1.1-3.5 |

22 |

5.6 |

|

Φ1200*2400 |

36 |

3 |

<=25 |

0.075-0.6 |

1.5-4.8 |

30 |

12 |

|

Φ1200*3000 |

36 |

3.5 |

<=25 |

0.074-0.4 |

1.6-5 |

37 |

12.8 |

|

Φ1200*4500 |

32.4 |

5 |

<=25 |

0.074-0.4 |

1.6-5.8 |

55 |

13.8 |

|

Φ1500*3000 |

29.7 |

7.5 |

<=25 |

0.074-0.4 |

2-5 |

75 |

15.6 |

|

Φ1500*4500 |

27 |

11 |

<=25 |

0.074-0.4 |

3-6 |

110 |

21 |

|

Φ1500*5700 |

28 |

12 |

<=25 |

0.074-0.4 |

3.5-6 |

130 |

24.7 |

|

Φ1830*3000 |

25.4 |

11 |

<=25 |

0.074-0.4 |

4-10 |

130 |

28 |

|

Φ1830*4500 |

25.4 |

15 |

<=25 |

0.074-0.4 |

4.5-12 |

155 |

32 |

|

Φ1830*6400 |

24.1 |

21 |

<=25 |

0.074-0.4 |

6.5-15 |

210 |

34 |

|

Φ1830*7000 |

24.1 |

23 |

<=25 |

0.074-0.4 |

7.5-17 |

245 |

36 |

|

Φ2100*3000 |

23.7 |

15 |

<=25 |

0.074-0.4 |

6.5-36 |

155 |

34 |

|

Φ2100*4500 |

23.7 |

24 |

<=25 |

0.074-0.4 |

8-43 |

245 |

42 |

|

Φ2100*7000 |

23.7 |

26 |

<=25 |

0.074-0.4 |

8-48 |

280 |

50 |

|

Φ2200*4500 |

21.5 |

27 |

<=25 |

0.074-0.4 |

9-45 |

280 |

48.5 |

|

Φ2200*6500 |

21.7 |

35 |

<=25 |

0.074-0.4 |

14-26 |

380 |

52.8 |

|

Φ2200*7000 |

21.7 |

35 |

<=25 |

0.074-0.4 |

15-28 |

380 |

54 |

|

Φ2200*7500 |

21.7 |

35 |

<=25 |

0.074-0.4 |

15-30 |

380 |

56 |

|

Φ2400*3000 |

21 |

23 |

<=25 |

0.074-0.4 |

7-50 |

245 |

54 |

|

Φ2400*4500 |

21 |

30 |

<=25 |

0.074-0.4 |

8.5-60 |

320 |

65 |

|

Φ2700*4000 |

20.7 |

40 |

<=25 |

0.074-0.4 |

12-80 |

400 |

94 |

|

Φ2700*4500 |

20.7 |

48 |

<=25 |

0.074-0.4 |

12-90 |

430 |

102 |

|

Φ3200*4500 |

18 |

65 |

<=25 |

0.074-0.4 |

----- |

800 |

137 |

Get a Quote