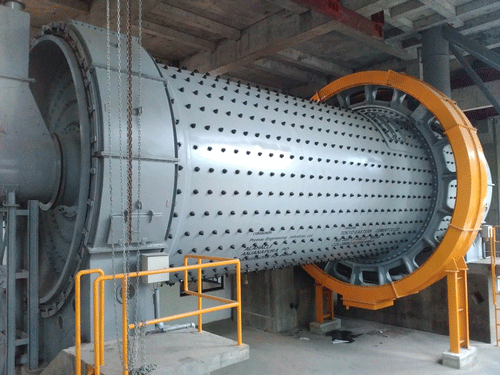

cement mill

Usage and application:

The cement mill is the key equipment for re-grinding cement clinker after pre-grinding by system ingredients. It plays a vital role in the cement production line and cement production process. Cement mills are mainly used in cement, silicate products, new building materials, refractory materials, glass ceramics, and other production industries.

Working principle:

When the cylinder of the grinding mill rotates driven by the transmission gear, under the inertial centrifugal force, the grinding media will stick onto the lining board on the internal wall of the cylinder of the grinding mill and rotate together with the cylinder. The grinding media are brought to a certain height, and then fall down under the gravity, and during this process, the grinding media will crush the materials inside the cylinder, and at the same time the grinding media repeatedly move up and down inside the rotating grinding mill and will have sliding and rolling movement, so that the grinding media, the lining board and the materials to be ground will grind with each other, so that the materials are crushed to a finer granularity.

Features:

Using advanced process design, the cylinder is tightly sealed to ensure dust overflow during operation.

The cylinder is cast with high-quality steel to extend the service life.

The good effect of saving energy, strong durability, low cost of grinding

The machine output can be increased by 15-20% compared with the general cement mill. the power consumption is reduced by about 10%

Technical specifications:

|

Specification (m) |

Capacity (t/h) |

Rotating speed (r/min) |

Grinding body (t) |

Motor |

Reducer |

Weight (t) |

||

|

Model |

Power (kW) |

Model |

Speed ratio |

|||||

|

Φ1.2x4.5 |

1.4 |

30.3 |

5 |

YR250M-6 |

55 |

ZD30-8 |

4.481 |

13.1 |

|

Φ1.5x5.7 |

3.5 |

26.34 |

11 |

JR127-8 |

130 |

ZD40-7 |

4 |

25 |

|

Φ1.83x6.4 |

6 |

23.9 |

18 |

JR137-8 |

210 |

ZD60-8 |

4.5 |

35.3 |

|

Φ1.83x7 |

6.5 |

24.5 |

20 |

JR138-8 |

245 |

ZD60-8 |

4.5 |

37.2 |

|

Φ2x9 |

9.5-10 |

23.88 |

31 |

JR158-8 |

380 |

ZD70-8 |

4.5 |

58.4 |

|

Φ2.2x6.5 |

11 |

21.4 |

30 |

JRQ158-8/YR630-8 |

380 |

ZD70-9 |

5 |

46.2 |

|

Φ2.2x6.5 |

14 Closed circuit |

21.4 |

30 |

JRQ158-8/YR630-8 |

380 |

ZD70-9 |

5 |

46.2 |

|

Φ2.2x7 |

12 |

21.4 |

30 |

JR158-8 |

380 |

ZD70-9 |

5 |

54 |

|

Φ2.2x7.5 |

13 |

21.4 |

32 |

JR158-8 |

380 |

ZD70-9 |

5 |

63 |

|

Φ2.2x8 |

14 |

21.4 |

37 |

JR158-8 |

380 |

ZD70-9 |

5 |

65 |

|

Φ2.2x9.5 |

14-16 Closed circuit |

21.4 |

43 |

JR1510-8 |

475 |

ZD70-9 |

5 |

70 |

|

Φ2.2x13 |

16 |

20.3 |

55 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.3/99.96 |

114.4 |

|

Φ2.4x7 |

14-16 Closed circuit |

20.4 |

36 |

JR1510-8 |

475 |

JDX450 |

5 |

67.9 |

|

02.4x8 |

16-17 Closed circuit |

20.3 |

41 |

JR1512-8/Y180L-8 |

570/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

87.2 |

|

Φ2.4x9 |

17-19 Closed circuit |

20.3 |

46 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

93.5 |

|

Φ2.4x10 |

18-19 Open circuit |

20.3 |

50 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

99.4 |

|

Φ2.4x11 |

19-21 Open circuit |

20.3 |

60 |

YR630-8/1180/Y100L-8 |

630/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

99.4 |

|

Φ2.4x12 |

25-27 Closed circuit |

20.3 |

61 |

YR800-8/1180/Y100L-8 |

800/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

112.7 |

|

Φ2.4x13 |

25-27 High fine open circuit |

20.3 |

66 |

YR800-8/1180/Y100L-8 |

800/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

131.1 |

|

Φ2.4x13 |

21-23 Open circuit |

20.3 |

66 |

YR1000-8/1180/Y160M-4 |

1000/11 |

JD630/ZS82.5-7 |

6.333/99.96 |

130.4 |

|

Φ2.6x10 |

25-27 Closed circuit |

20.3 |

60 |

YR800-8/1250 |

800 |

JD800 |

5.5 |

150.5 |

|

Φ2.6x13 |

27-29 |

19.1 |

80 |

YR1000-8/1180/Y160M-4 |

1000/11 |

|

5.5/280 |

169 |

|

Φ3x9 |

33-34 Closed circuit |

19.6 |

79 |

YR1000-8/1180/Y160M-4 |

1000/11 |

NAL108/8/ZS110-19 |

8/280 |

156.5 |

|

Φ3x9 |

36.5 Closed circuit |

17.6 |

79 |

YR118/61-8 |

1000 |

2x1250 |

42.163 |

121.13 Without motor |

|

Φ3x11 |

35-40 Closed circuit |

18.3 |

97 |

YR1250-8/1430/YR160M-4 |

1250/11 |

YNL1210 |

6.3 |

178 |

|

Φ3x11 |

47 Closed circuit |

17.7 |

97 |

YR118/74-8 |

1250 |

ZI314 |

42.39 |

169 |

|

Φ3x12 |

38-40 Closed circuit |

18.1 |

90 |

YR1250-8/1430 |

1250/11 |

JS1100-00 |

41.27 |

196.26 |

|

Φ3.2x11 |

40 Closed circuit |

18 |

103 |

YR1400-8/1430/Y160M-4 |

1400/11 |

YNL1210/ZS110-19 |

12.35/28 |

186.1 Without motor |

|

Φ3.5x11.5 |

65-70 Closed circuit |

16.5 |

129 |

TYD143/49-8 |

2000 |

ZI370 |

36.239 |

138.3 Without motor |

|

Φ3.5x11.5 |

50 Closed circuit |

17.2 |

126 |

YR1800-8/1430/Y200L2-2 |

1800/37 |

|

43.02/318 |

252.27 |

|

Φ3.8x13 Double slipper |

70-75 Closed circuit |

16.6 |

170 |

YRKK800-8 |

2500 |

JS130/MFY250 |

44.9 |

203 Without motor |

|

Φ3.8x13 |

60-62 |

16.3 |

170 |

YR2500-10/1730 |

2500 |

MFYX250 |

|

286 |

|

Φ4x13 |

65 Closed circuit |

15.95 |

202 |

YRKK900-8 |

2800 |

JS130-8 |

46.7 |

264 |

|

Φ4.2x13 |

85 Closed circuit |

16.3 |

224 |

YRKK900-8 |

3150 |

MFY320 |

47.8 |

250 Without motor |

Get a Quote