fertilizer production line

Usage and application:

Compound fertilizer production line is widely applied to produce compound fertilizer and the capacity ranges from 5000-200,000 tons/year. It can granulate NPK, NP, ANP, DAP, MAP, CAN, SSP and other materials into compound fertilizer particles in one processing line. This equipment is specially used for manufacturing compound fertilizers with different concentrations and types, such as organic fertilizers, inorganic fertilizers, biological fertilizers and magnetic fertilizers, etc. It is mainly used for producing spherical particles with a diameter ranging from 1mm to 3mm.

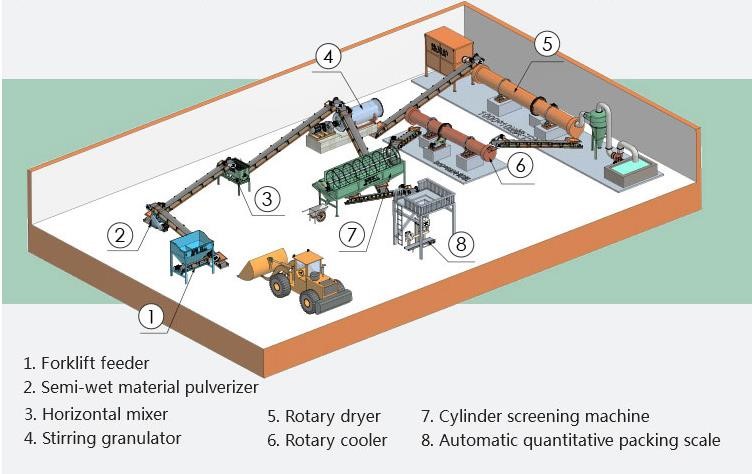

Working process of Granular Fertilizer Production Line:

Working process of Granular Fertilizer Production Line:

Raw material fermentation-Raw material crushing-Raw material mixing -Raw material drying-Fertilizer granulating -Fertilizer cooling-Fertilizer coating-Fertilizer packing

Features:

The compound fertilizer production line has less investment, quick results and good economic benefits. The whole equipment process is compact, scientific and advanced. Energy saving and consumption reducing, no waste removal, stable operation, reliable running, convenient maintenance. The adaptability of raw materials is wide, and the machine is suitable for the granulation of compound fertilizer, medicine, chemical industry, feed, etc., and the granulation rate is high.

Technical specifications:

|

Model |

Capacity(t/h) |

Feature |

|

Organic drum granulation production line |

0.5-20t/h,1000-200000t/year |

Raw material is power, add to 40% humidity,then make granules,dry granules. |

|

Organic granulation production line |

0.5-20t/h,1000-200000t/year |

Raw material is power, add to 40% humidity,then make granules,dry granules. |

|

Disc granulation production line |

0.5-20t/h,1000-200000t/year |

Raw material is power, add to 40% humidity,then make granules,dry granules. |

|

Roller press granulation production line |

0.5-20t/h,1000-200000t/year |

Raw material is power, add to 2%-6% humidity, then make granules, don't need dry |

Get a Quote