gold centrifugal concentrator

Usage and application :

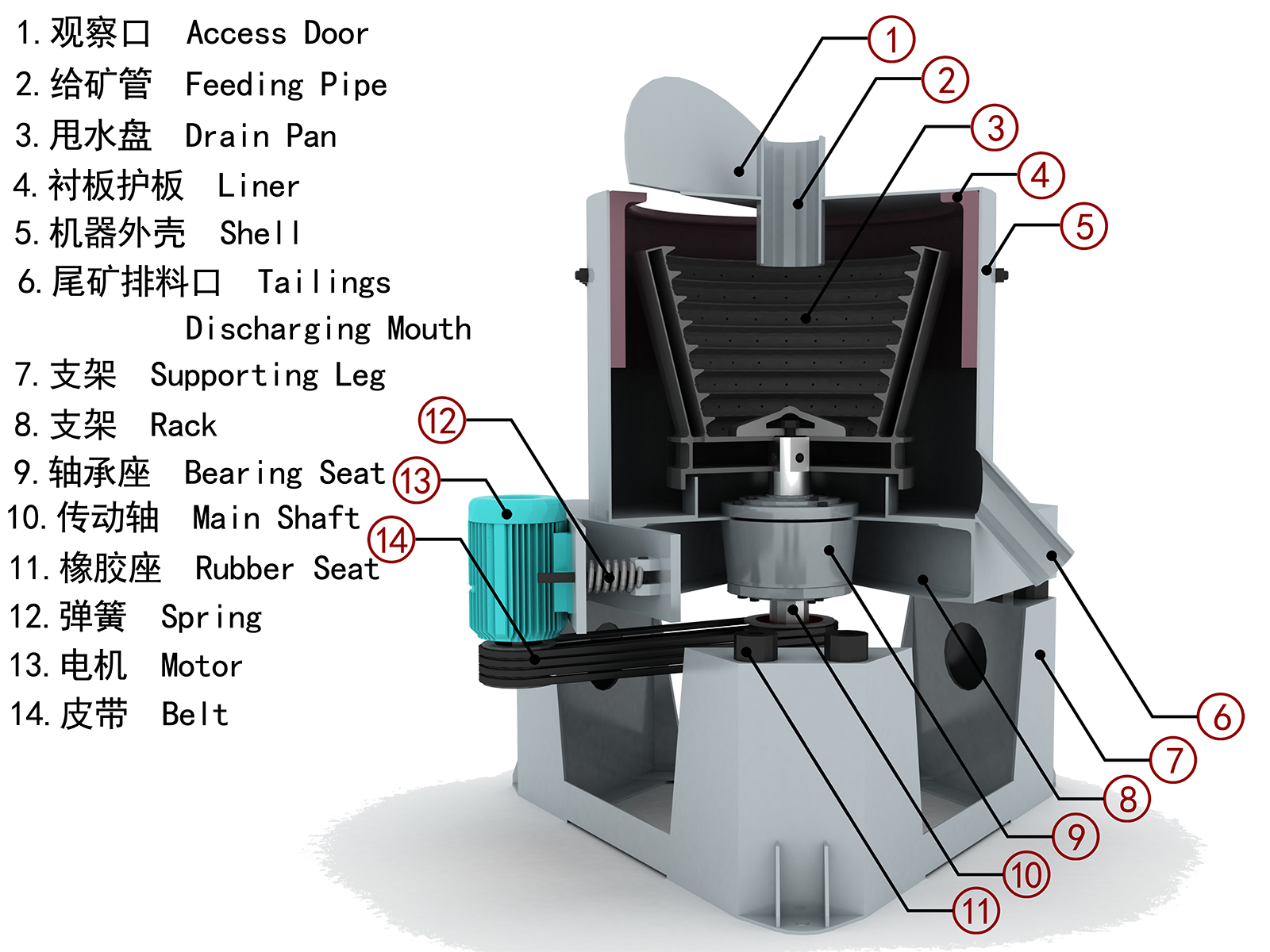

Gold centrifugal Concentrator is a new type of gravity concentration equipment for gold separating and other high density minerals. The centrifugal machine has many competitive advantages compared with other concentration machines which create high returns for the investors.

working principle:

The main shaft is a hollow shaft, the pressurize backwash water come from the shaft, then goes into the separation unit, the water spray from holes to the gratings. During the process, the pressure of the water shall be 0.06-0.15MPa. The slurry which is mixed with water and ore and sand will be injected to the mainframe. With the heavy centrifugal force, the slurry will be move upward along the cone body, the light particles will be extracted from the upper part of cone, then discharge through the tailing outlet.The heavy particles will be stay in the gratings of the inner layer.

Features:

- High recovery and high concentrating ratio

2.Recovery performance is steady

3.Has a centre discharge design that enables fast and secure concentrate removal

4.Eco friendly ( needs no reagents or chemical additives)

5.Low electricity and low water requirements

6.Low cost of production, low maintenance requirements with durable wear parts

7.Has a compact design needing less space and can be easily merged into an existing mining processing

8.Fast returns on investment, usually less than 6 months.

Technical specifications:

|

Model |

Capacity (t/hr) |

Feeding Size(mm) |

Feeding Density(%) |

Power Requirement (kw) |

Cone Rotate Speed |

Water Required(t/h) |

Dimension(mm) |

|

STLB20 |

0.5-1.0 |

0-2.5 |

0-50 |

1.1 |

800 |

1.5-2.0 |

800*560*710 |

|

STLB30 |

2.0-3.0 |

0-4 |

0-50 |

2.2 |

600 |

4.0-6.0 |

1280*1030*1135 |

|

STLB60 |

8.0-12.0 |

0-6 |

0-50 |

7.5 |

460 |

10.0-15.0 |

1850*1550*1600 |

|

STLB80 |

10.0-20.0 |

0-6 |

0-50 |

15 |

400 |

17.0-25.0 |

2300*1800*2200 |

|

STLB100 |

50-100 |

0-6 |

0-50 |

18 |

360 |

40.0-60.0 |

2400*2400*2250 |

Get a Quote